The first low-cost system for splitting carbon dioxide

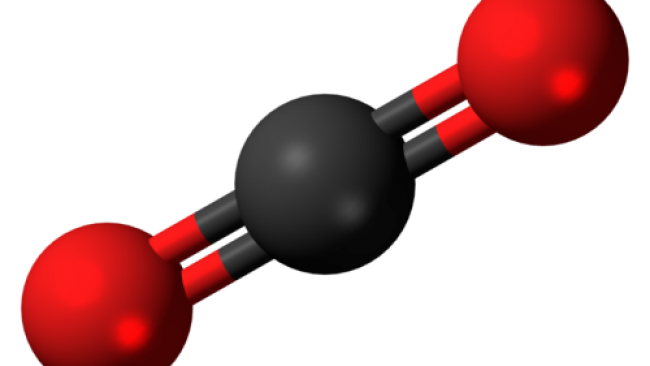

Using Earth-abundant materials, EPFL scientists have built the first low-cost system for splitting CO2 into CO, a reaction necessary for turning renewable energy into fuel.

The future of clean energy depends on our ability to efficiently store energy from renewable sources and use it later. A popular way to do this is to electrolyze carbon dioxide to carbon monoxide, which is then mixed with hydrogen to produce liquid hydrocarbons like gasoline or kerosene that can be used as fuel. However, we currently lack efficient and Earth-abundant catalysts for the initial splitting of CO2 into CO and oxygen, which makes the move into renewable energy expensive and prohibitive. EPFL scientists have now developed an Earth-abundant catalyst based on copper-oxide nanowires modified with tin oxide. The system can split CO2 with an efficiency of 13.4%. The work is published in Nature Energy, and can help worldwide efforts to synthetically produce carbon-based fuels from CO2 and water.

The research was carried out by the lab of Michael Grätzel at EPFL. Grätzel is known worldwide for the invention of the first ever dye-sensitized solar cells (or "Grätzel cells"). The catalyst, developed by PhD student Marcel Schreier and postdoc Jingshan Luo, is made by depositing an atomic layer of tin oxide on copper oxide nanowires. By using such Earth-abundant materials, the design keeps the cost of the catalyst low while significantly increasing the yield of CO, as opposed to the other products that are generated from CO2 electrocatalysis.

The catalyst was integrated into a CO2 electrolysis system and linked to a triple-junction solar cell (GaInP/GaInAs/Ge) to make a CO2 electrolyzer. The system uses the catalyst as a bifunctional electrode that both reduces CO2 into CO and produces oxygen through what is known as the "oxygen evolution" reaction. The two products are separated with a bipolar membrane.

Using solar energy, the system was able to selectively convert CO2 to CO with an efficiency of 13.4%, and do so with a Faradaic efficiency up to 90%—this describes how efficiently electrical charge is transferred in a electrocatalysis system like the one developed here. "The work sets a new benchmark for solar-driven CO2 reduction," says Luo.

"This is the first time that such a bi-functional and low-cost catalyst is demonstrated," adds Schreier. "Very few catalysts—except expensive ones, like gold and silver—can selectively transform CO2 to CO in water, which is crucial for industrial applications."

Source: Phys.org

Tue 6 Jun 2017 at 08:31

.png)

.png)